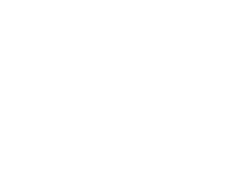

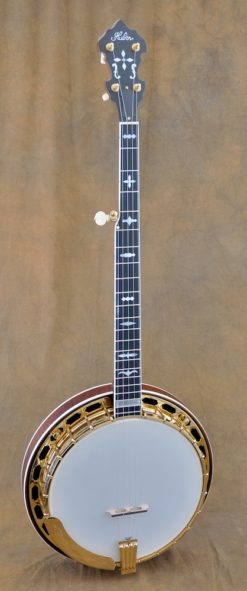

The Roanoke features a straight grain walnut neck. Banjo players who favor the older instruments always rave about the sound, but also include the feel of the necks and their ease of playability in describing their preference for the prewars.

With this in mind, Steve carefully digitized the neck of his favorite old banjo, capturing every curve and nuance. The Huber necks are produced using computer-aided machining technology, ensuring that each neck is crafted to the exact prewar specifications – every time!

The back of the Roanoke resonator has an overlay of figured walnut, while the side walls and neck feature straight grain walnut.

Resonators are built by Steve’s dad, Jack Huber, in Lancaster PA.

The Standard Huber inlay pattern is used for the Lancaster, Kalamazoo, Roanoke, and Lexington models. This pattern was designed by Steve Huber and his brother Dave, and has been in use since Huber Banjos’ inception. Dave Huber cuts all of the pearl on a CNC machine and inlays all the necks. His care and attention to detail add substantially to the beauty of these fine instruments.

The headstock overlay is slightly more ornate on the Roanoke and Lexington models but the fingerboard patterns are the same on all four.

The pearl block inlay at the 21st fret is engraved with the name of this model, the “Roanoke”.

The binding along both the fingerboard and the resonator side walls is trimmed with a decorative strip of white/black/white.

All of the Huber Banjos come with Waverly V-2 tuners installed. The V-2s work very well and closely approximate the look of those found on vintage banjos. The tapered underside of the peghead washer helps protect the headstock and the internal low-friction bushings help ensure smooth operation.

The tuners are fitted with authentic recreations of 1930’s “Amber Tulip” buttons and help create the proper vintage feel.

All stock models are made with a rosewood fingerboard.

The Huber bridge is made of carefully selected maple and ebony and is designed for tone, volume, and clarity. String slots are cut with a custom-built slotting machine that produces the exact depth, spacing, and angle every time.

The Huber bridge is also available as a separate accessory item order.

Our HR-30 Tone Ring represents the pinnacle in prewar reproduction, measured in both tone and responsiveness. It was created after a year of analysis into the vibratory physics of more than a dozen prewar flathead rings, and further research into casting methods that could consistently reproduce a ring that closely matched our prewar standard.

The Huber Engineered Rim is the ultimate in tone and response, developed over a year of extensive scientific measurement and careful prototyping.

Dr. Jim Rae is the brains behind the Engineered Rim. Dr. Rae analyzed the vibrational physics and sonic output of prewar rims and used these numbers as the benchmark. Brian Sims worked with Dr. Rae in the prototyping and manufacturing of the Engineered Rim.

Through a special arrangement with Remo, Huber installs a head on each new banjo that is manufactured to his custom specifications. Steve finds that they offer a superior tone to that of the stock Mylar heads offered for banjo.

These Huber heads can also be ordered as a separate, after-market accessory item.

We use a two way adjustable truss rod in our necks. The two way rod allows for adjustments in both directions – you can add relief or reduce bow as needed.

The rod is accessible under the truss rod cover in the headstock, just behind the nut.

Our Roanoke model is stained in a natural walnut to enhance the color and grain of the wood.

All Huber banjos are finished with multiple layers of nitrocellulose lacquer, hand sanded between coats for a smooth appearance. They are then buffed to a high gloss with careful attention to detail at every step in the finishing process.

The Roanoke features beautiful polished nickel plated metal.

Like the storied pre wars which inspired them, most Huber Banjos have a Presto-style tailpiece installed during final assembly and set up. Steve feels that the lighter weight of this sort of tailpiece is best suited to the sound he is after.

The pot-metal flange we use in all Huber Banjos is custom machined in a process which allows for more solid contact between the flange and rim, resulting in better structural stability and tonal response.

On all our models, we use a brass notched tension hoop, plated to match the other metal parts.

We use plated steel rods to hold the neck onto the rim instead of the softer brass found in many new banjos. We chose steel rods since the older flatheads used them and, proving that no detail is too small, even the nuts and washers are exact prewar replicas!

Each Huber banjo is shipped in its own plush lined hard shell case.The top lid is arched for superior protection.

Every Huber Banjo is warranted to the original owner without time limit, often described as a “Limited Lifetime Warranty.”

Any defect in material or workmanship, except heads, strings and pegs will be repaired or replaced free of charge to the original owner, if returned to our factory, charges prepaid.

Larry Hounshell –

Steve built me a custom Roanoke based banjo with Lexington engraving and gold plating. I wanted the wreath inlays, ebony radiused fingerboard, speed neck, and fiddle cut peghead. This banjo is hands down the best sounding and playing banjo I have ever played. Everyone that has played it has said the same thing. Can’t beat a Huber.