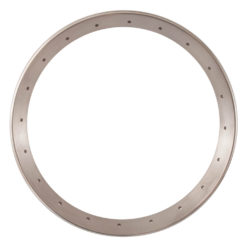

Huber Engineered Rim

$300.00 – $445.00Price range: $300.00 through $445.00

Like the Huber HR-30 tone ring, the Huber Engineered Rim is the result of extensive and detailed scientific measurement of the acoustical properties of pre-war banjo rims. The bottom line is the better the rim vibrates, the better the banjo sounds! This is the rim we use in our Truetone banjos. It is, without a doubt, the finest banjo rim available today.

Engineered Rim Development

The Huber Engineered Rim was created through the same process of testing and development that gave birth to the Huber HR-30 tone ring.

During testing, 28 prewar rims were carefully analyzed, with 2 selected for more detailed measurement after a subjective determination that they generated the best results with other prewar components. In this further testing, the vibrational properties of these rims were plotted, providing us with a scientific benchmark for the development phase which followed.

We started by perfecting procedures for selecting suitable woods at the lumber yard. The properties of the prewar rims were known, so only new wood that was a close match would do. This new wood then underwent further testing to determine what changes would be necessary to make the wood match the properties of the prewar rim wood.

This required working out ways to treat the wood that modified its vibrational properties in repeatable and measurable ways. Many measurements were taken, with multiple repeats of the processes, to determine how successfully we could replicate the desired properties in a new rim. It was equivalent to “tuning” the wood to the desired properties.

Like the Huber HR-30 tone ring, our new Engineered Rim is the result of the most extensive, scientific and detailed measurement of the acoustical properties of pre war banjo components ever performed.

Though Steve Huber first made his name for his Huber Vintage Flathead tone ring, he has long known that the rim is every bit as important a component in creating the optimal tone and response from a banjo. As he likes to say, if the tone ring is the engine of a banjo, the rim is the frame on which it sits.

As he became more and more familiar with dozens of pre war flatheads, Steve took note of certain banjos that stood above the rest – the best of the best. These were the banjos which were selected for our testing.

This was a rigorous and sophisticated study, incorporating the analytical expertise of Dr. Jim Rae, a recently-retired research scientist from Mayo Clinic. Rae made his mark with groundbreaking research into techniques for measuring the tiny currents that flow through individual protein molecules called ion channels many of which are involved in diseases of the heart, nervous system, hearing, vision and many other human organ systems. Many aspects of this research used techniques that are also used in physical acoustics.

After his retirement, Jim created a lab at his home to study the physical acoustics of 5-string banjos. He has published several papers and a book chapter in the scientific literature dealing with banjo vibrations and sound emission.

Jim, or “Doc Rae” as Huber calls him, had also developed a fascination with the banjo and agreed to use his gear to define the ways in which rims from these exceptional banjos differed from the run-of-the-mill. Doc Rae studied the vibrational characteristics of these rims, and helped us develop methods for choosing wood that would give our new rims these same qualities.

[vc_separator type=’normal’ position=’center’ color=” border_style=” thickness=” up=” down=”]

Huber Engineered Rim Research

The Huber Engineered Rim was developed using similar approaches and measurements as those used for the development of the HR-30 ring. The studies have taken almost two years to reach the point where we believe they are ready to go into finished banjos.

Initially, the vibration properties were measured for 28 isolated Gibson prewar rims. Of those, two were deemed by knowledgeable listeners to make the best sounding banjos when used with other Gibson prewar banjo parts.

The goal then was to design 3-ply rims that matched these two prewar rims. This required developing quantitative procedures for selecting wood at the lumber yard. When this was accomplished, detailed measurements of the wood’s vibrational properties were done to determine what changes would be necessary to make the wood match the properties of the prewar rim wood.

This required working out ways to treat the wood that modified its vibrational properties in repeatable and measurable ways. Many measurements were taken as well as repeats of the processes to determine levels and durations that resulted in the desired wood properties. It was equivalent to “tuning” the wood to the desired properties.

This was done on every ply of every potential rim and then the plys were assembled so as to best match the prewar rim properties. We also had good measurements to quantify the vibration transfers that occurred between the original prewar rims and their prewar rings when the ring was sitting on top of the rim on isolation mounts. The best pairs showed substantial ability for the vibrations to flow between ring and rim.

So, this criterion was also incorporated in the design requirements for the Huber HR-30 rings and the Huber Engineered rims. Not only did each part vibrate in ways we could control but they also matched to an extent that vibration transfer between the two was facilitated. To date, only about 15% of the starting plys match the stringent requirements we have set and thus end up in Huber Engineered rims.

[vc_separator type=’normal’ position=’center’ color=” border_style=” thickness=” up=” down=”]Huber Engineered Rim Manufacturing

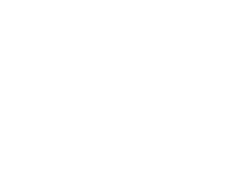

Our Huber Engineered Rims are built by Bryan Sims to the specs developed by Doc Rae.

What our testing revealed is that not just any piece of wood is capable of delivering the rich tone and quick response associated with pre war banjos. Doc Rae discovered the properties that are required for a great rim, and we grade and process our wood with particular care to match his profile.

Bryan carefully picks through lumber to select only the pieces that fit our requirements, and even then, most of the pieces he chooses for rim plies do not make the cut. He says that this process generates a great deal of wasted wood, but that there is no other alternative to achieving the result we are after – rim after rim.

Our testing also identified specific methods for gluing the plies together that would consistently yield the best results, and Bryan follows them to a “t.”

The completed rims are then further tested to ensure that they match the specs before they get the Huber Engineered Rim stamp.

| Weight | 3 lbs |

|---|---|

| Rim Options | Stained & Laquered, Turned & Drilled |

| Rim Finish | Style #3, Style #4, Style Granada, Unfinished |

1 review for Huber Engineered Rim

Add a review Cancel reply

Related products

Apparel

Huber Accessories

Huber Parts

Parts & Accessories

Huber Accessories

Huber Accessories

Huber Accessories

Huber Parts

Rufus Bigford (verified owner) –

This Rim has absolutely improved the sound of my banjo. It is a model I built myself years ago and it already had a great sound. However I was not prepared for the increased tone and clarity it now has. Steve took the time to ensure that the rim was machined to an exact fit of my tone ring and flange. His attention to me as a customer to make sure that I had the best result possible will not be forgotten. I highly recommend this Rim, but more importantly, I recommend doing business with this company.